end-to-end fiber-optic solutions

solutions to Indian as well as Global customers

cleaner and greener future

demands for electric vehicles

wiring harness requirements

Automotive Standards

About Us

HTL Ltd., a subsidiary of HFCL Ltd. (formerly Himachal Futuristic Communications Ltd.), has set up state-of-the-art infrastructure in

the heart of Chennai for manufacturing Optical Fiber Cables (OFC) and providing

Passive Connectivity Solutions. The plant, spread over 20 acres, has annual

capacity to manufacture 11.88 million fiber km of cables. It also has a plant in Hosur (Tamil Nadu), where the

critical raw materials required for OFC such as Aramid/Kevlar Rods (ARP), Fiber Reinforced Plastic Rod (FRP) and Impregnated Glass Fiber Reinforcement (IGFR)

are manufactured.

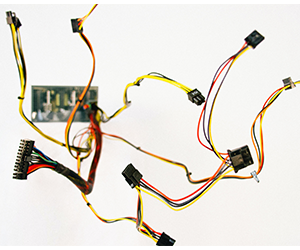

Very recently, the Company has also diversified into Electrical Wiring Interconnect Solutions (EWIS) and have subsequently set up a production facility within its Chennai plant to cater to Aerospace & Defence and Automotive & Industrial markets. Multiple line audits and industry accreditation are in progress for this newly initiated ventures more so in the Quality Management System (QMS) domain whether be it the IATF 16949 Certification pertinent to Automotive industry or AS9100:2016 in the Aerospace industry.

HTL Ltd, over the years, has gone on to receive much

needed industry accreditation from International Organization for

Standardization (ISO) for our product lines such as OFC, Components for OFC

& Passive Connectivity Solutions. The ones received till date are TL9000-H & ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, ISO 27001:2013 and ISO 22301:2019.

Why HTL?

- Huge experience in making cable and cable assemblies

- Smart manufacturing facility

- Geographic advantage of being located near airport and seaport - for exports

- Involved leadership for success in customer programs

- 100% Quality Assurance

Industries We Serve

Innovation at HTL

With the new technological advances in the field of telecommunication, the demand for higher data transmission has gone up drastically. HTL specializes in Optical Fiber Cables and accessories, for backbone and last-mile network, which have numerous advantages over other transmission media in terms of speed and space constraints. That’s why our engineering team continuously works on innovating new designs of cable that supports a large volume of data transmission.

In order to match the demand for the larger volume of data transmission higher fiber count cables are required to fulfill the purpose of easy installation and to meet the customer needs, which is a continual improvement process HTL has developed as a habit. The transformation from uni-tube cables to multi-tube cables, the upcoming of ribbon cables and now micro-modules; there is a massive transformation in the industry, with manufacturers forced to ensure low costs and high quality. This sudden change in demand has also led to the development of high-quality passive components with higher durability and huge versatility.