Infrastructure

HTL's EWIS Division operates from a modern facility in Hosur, Tamil Nadu. This advanced manufacturing hub is designed to deliver high-quality Electrical Wiring Interconnect Systems (EWIS) for both the

Aerospace & Defence (A&D) and Automotive & Industrial (A&I) sectors. Equipped with state-of-the-art technology and machinery, our facility is capable of handling a wide range of processes, meeting the

stringent standards of both industries.

We cater to a variety of customer-specific orders, including low-volume, high-mix, and high-volume, low-mix production requirements. Our extensive capability in EWIS includes Identification marking,

Cable harness assembly, Advanced joining processes, Injection molding, Braiding, Potting & Ruggedization, PCB assembly, and the development of high-precision test equipment. In our Wire Harness assembly

operations, we carry out key processes such as auto wire cutting, crimping, cable processing, stripping, ultrasonic welding, and other assembly operations.

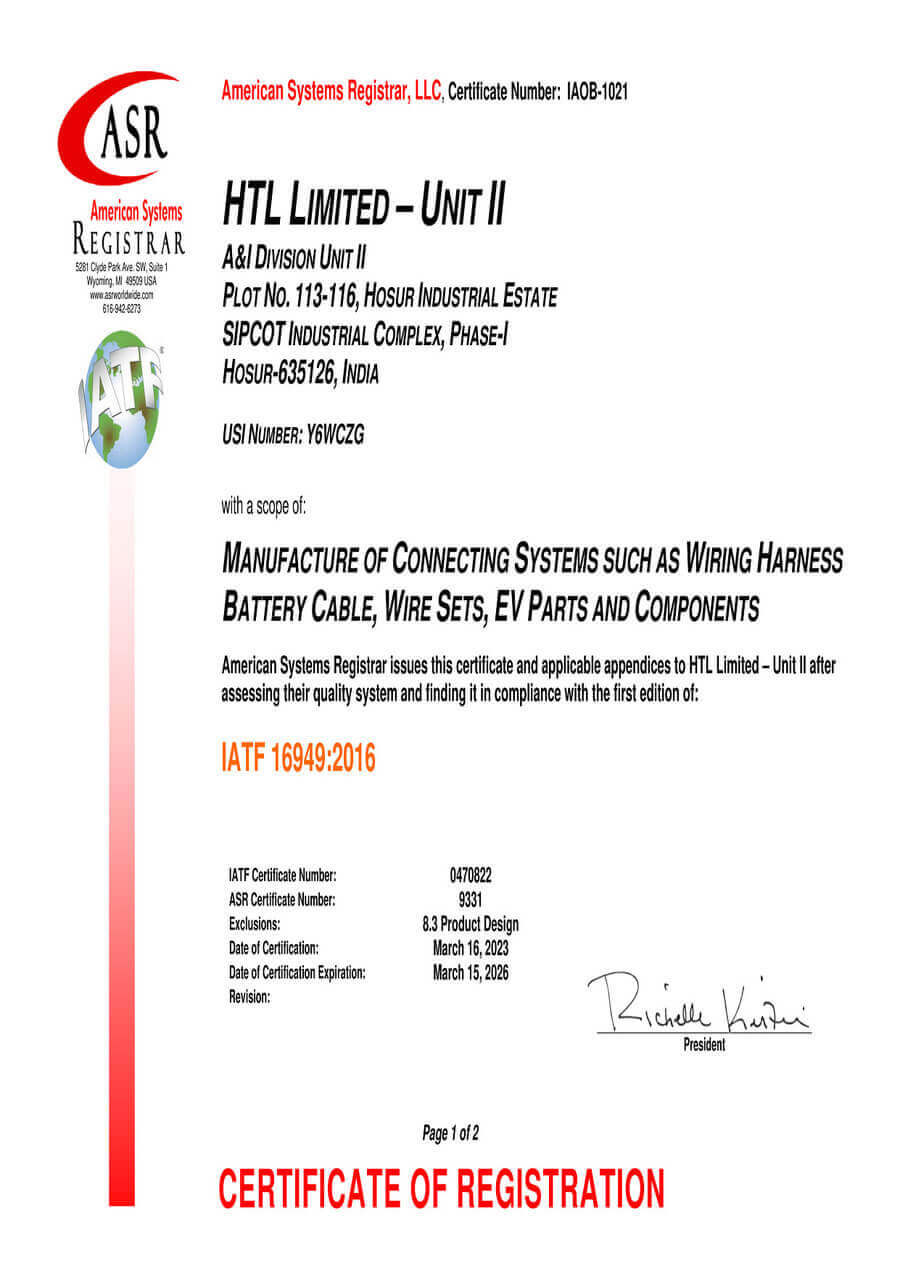

Our facility is certified to AS9100D, IATF 16949, ISO 9001, ISO 14001, and ISO 45001 standards, ensuring our products meet and exceed global benchmarks. Rigorous quality control processes, supported

by comprehensive testing capabilities adhering to ISO 6722-1 standards, guarantee the reliability of every product we deliver.

Our diverse manufacturing capabilities are powered by a skilled workforce and certified engineers, including IPC 620D-certified technicians and PMP-certified managers. By embracing a “Design to Delivery”

approach, we seamlessly integrate design, engineering, and manufacturing. Leveraging advanced CAD and harness design software, our teams deliver tailored solutions that minimize engineering changes,

optimize efficiency, and accelerate delivery timelines.

With a steadfast commitment to innovation and excellence, HTL continues to set benchmarks in delivering reliable and cost-effective EWIS solutions.