Battery Cable Harness

Transfers power from battery to various components of vehicle through main harness

Battery Pack Cable

Connects the individual cells of a battery pack to each other, creating a larger & more powerful battery

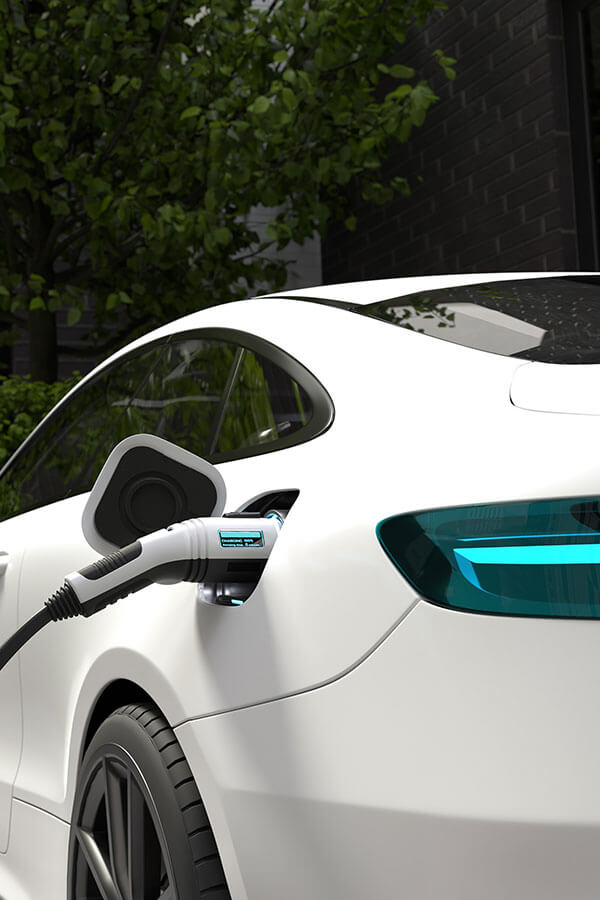

Charging Harness

Transfers electrical energy from the charging source to battery of the vehicle

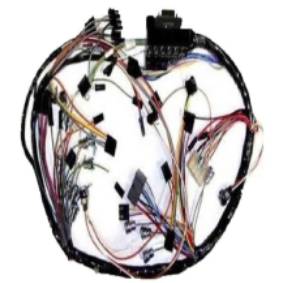

Main Harness

Connects the various electrical components of the vehicle to the battery

Motor Hub Harness

Transmits electrical power and signals between the motor hub and the battery, and other electrical components

Pigtail Harness

Connects various components of vehicles with main harness to carry out functions of Indicators, Spark plugs, Headlights, Cluster (display) etc.